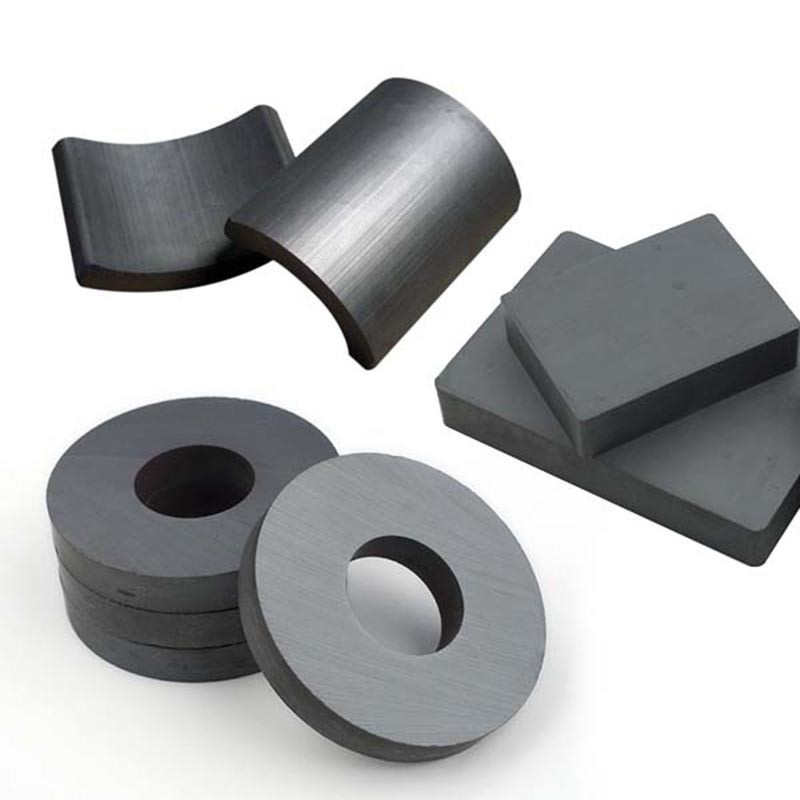

Round Ring Block Arc Permanent Ferrite Magnet

Product Description

The Ferrite Magnet (also known as a ceramic magnet ) is a permanent magnet.

They are mainly Strontium based (SrFe2O3), manufactured with Strontium Carbonate additive to increase performances from the obsolete Barium based (BaFe2O3).

Their good coercive force comes from the high crystal anisotropy of strontium iron oxide. However, isotropic parts can also be produced where a simple and easy multi-pole magnetization is required.

In terms of electrical characteristics, the resistivity of ferrite is much larger than that of metal and alloy magnetic materials, and it also has higher dielectric properties.

The magnetic properties of ferrite also show high permeability at high frequencies.

Ferrite is not conductive and has high resistance against corrosion, acids, salts, and lubricants. The most common shapes are simple, such as disc, blocks, cylinders, rings, and arcs.

Ferrite magnets are commonly used in various applications in the past several decades, such as loudspeakers, motors, and generators.

Magnetic Characteristics of Sintered Ferrite (China Standard)

|

Grade |

Remanence Induction |

Coercive Force |

Intrinsic Coercive Force |

Max.Energy Product |

||||

|

mT |

Gs |

k/Am |

kOe |

k/Am |

kOe |

kJ/m³ |

MGOe |

|

|

Y10 |

200-235 |

2000-2350 |

125-160 |

1570-2010 |

210-280 |

2640-3520 |

6.5-9.5 |

0.8-1.2 |

|

Y25 |

360-400 |

3600-4000 |

135-170 |

1700-2140 |

140-200 |

1760-2510 |

22.5-28.0 |

2.8-3.5 |

|

Y30 |

370-400 |

3700-4000 |

175-210 |

2200-2640 |

180-220 |

2260-2770 |

26.0-30.0 |

3.3-3.8 |

|

Y30BH |

380-400 |

3800-4000 |

230-275 |

2890-3460 |

235-290 |

2950-3650 |

27.0-32.5 |

3.4-4.1 |

|

Y33 |

410-430 |

4100-4300 |

220-250 |

2770-3140 |

225-255 |

2830-3210 |

31.5-35.0 |

4.0-4.4 |

|

Y35 |

400-420 |

4000-4200 |

160-190 |

2010-2380 |

165-195 |

2070-2450 |

30.0-33.5 |

3.8-4.2 |

Physical Properties of Sintered Ferrite

| Temp Coefficient of Br |

0-0.18 ~ -0.2 %/℃ |

Temp Coefficient of Hcj |

0.25-0.4%/℃ |

| Density |

4.7-5.1 g/cm³ |

Electrical Resistivty |

>10⁴ μΩ • cm |

| Vickers Hardness |

400-700 Hv |

Thermal Conductivity |

0.029 W/m • ℃ |

| Curie Temp |

450-460℃ |

Coefficient of Thermal Expansion |

9-10x10-6/℃ (20-100℃) ⟂C |

| Dpecific Heat |

0.62-0.85 J/g • ℃ |

Max. Operating Temp |

1 -40~ 250 ℃ |

| Bending Resitance |

5-10 Kgf/mm2 |

Compressive Resitance |

68-73 mm2 |