In the waste management and recycling industries, magnetic separators play a vital role in the efficient separation and removal of magnetic materials from waste streams. These remarkable machines are responsible for keeping our environment clean and preserving precious resources. At the heart of these separators lies an ingenious solution – magnetic materials.

1. Learn about magnetic materials:

To understand the significance of magnetic materials in magnetic separators, we must first understand the concept of magnetism. Magnetism is the property exhibited by certain substances to attract or repel other materials. This behavior is controlled by the arrangement of magnetic elements, or domains, within the material.

Magnetic materials can be divided into three main types: ferromagnetic, paramagnetic, and diamagnetic. Ferromagnetic materials are strongly magnetic due to their high sensitivity to magnetization. These materials are widely used in magnetic separators due to their excellent magnetic retention capabilities. Paramagnetic materials, on the other hand, exhibit weak magnetism and are affected by external magnetic fields. Diamagnetic materials exhibit no magnetic attraction and are even repelled by magnetic fields.

2. The role of magnetic materials in magnetic separators:

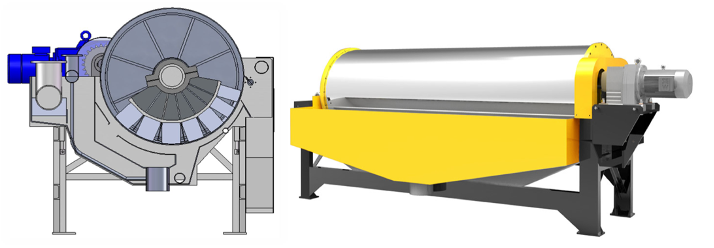

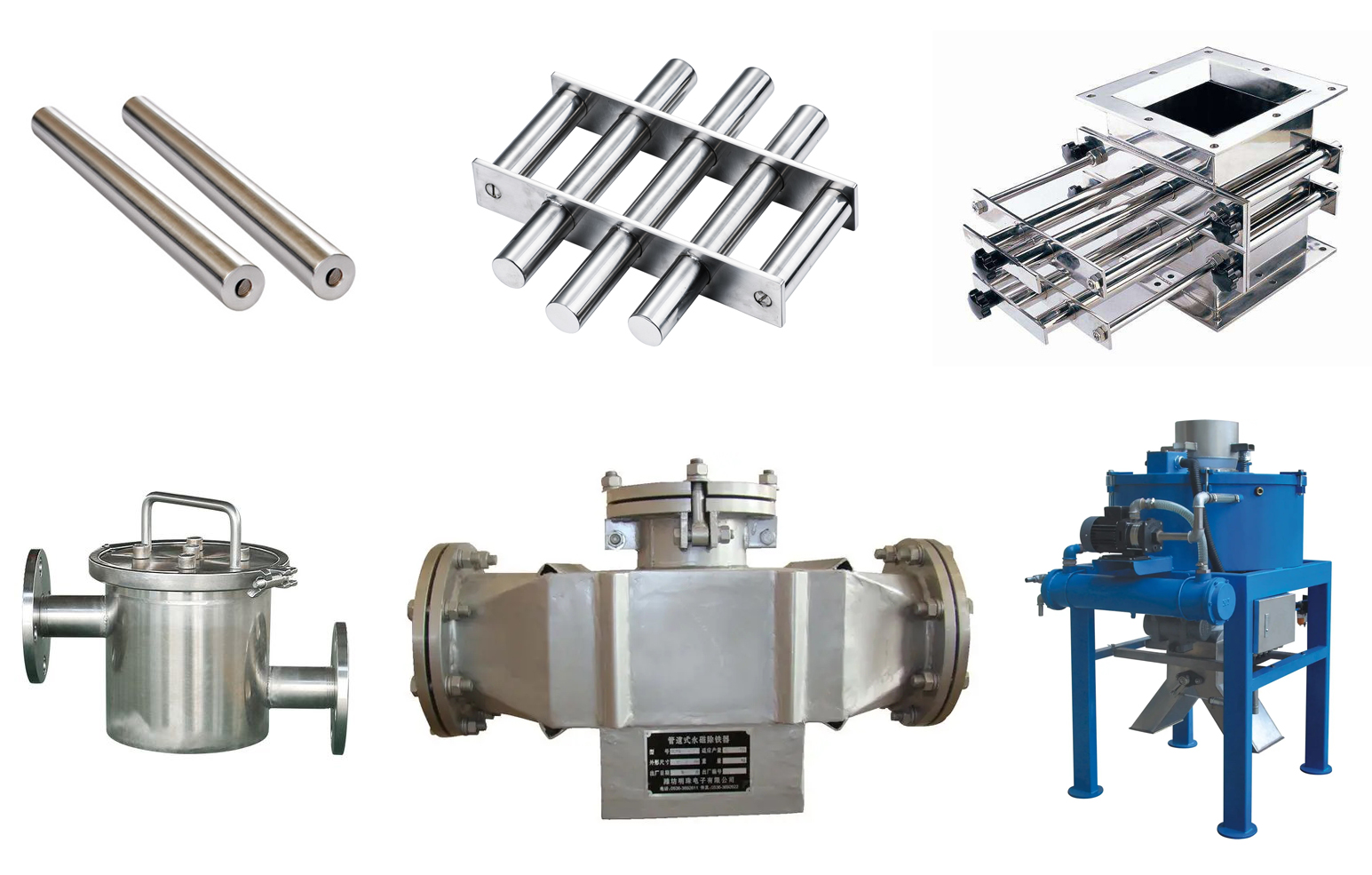

Magnetic separators are used to efficiently remove ferromagnetic contaminants from a variety of materials such as plastics, metals, minerals, and waste. The key component of these separators is the magnetic drum or magnetic plate, which contains an array of powerful magnets. These magnets are usually made of magnetic materials such as neodymium or ferrite , which create a strong magnetic field within the separator.

As the waste passes through the separator, ferromagnetic particles are attracted and adhere to the surface of the magnetic drum or magnetic plate. Non-magnetic materials, such as plastic or glass, continue on their intended path, ensuring proper waste sorting. The selective attraction of magnetic materials by magnetic separators enables efficient separation processes.

3. Advances in Magnetic Materials for Enhanced Separation:

Over the years, scientists and engineers have made significant advances in magnetic materials, further improving the efficiency and performance of magnetic separators. One such advancement is the use of rare earth magnets, specifically neodymium magnets . These magnets possess extremely strong magnetic fields, which allow for better separation of even the tiniest ferromagnetic particles. Their exceptional strength has revolutionized the recycling industry, ensuring higher purity and optimal resource recovery.

In addition, advances in magnet fabrication techniques and magnetic coatings have facilitated the development of hybrid magnetic materials. These hybrid materials combine different magnetic materials with different properties and are designed to optimize the magnetic field distribution within the separator and increase separation efficiency.

Magnetic materials are an integral part of magnetic separators and play a key role in waste management and recycling. Magnetic materials, through their extraordinary magnetism, effectively attract, collect and separate ferromagnetic contaminants, ensuring the purity of waste streams and preventing environmental contamination. As technology continues to advance, the field of magnetic materials will usher in promising innovations in the future, further improving the effectiveness and sustainability of magnetic separators, and ultimately benefiting our planet and industries.

Post time: Aug-18-2023