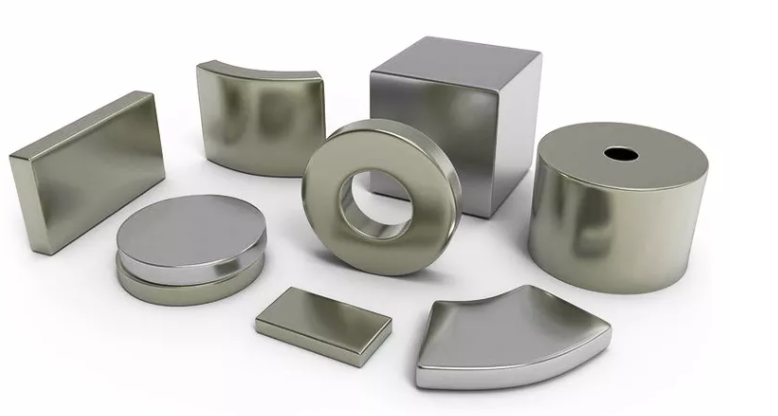

1. The neodymium magnets are usually made from a powdered alloy of neodymium, iron, and boron that is sintered together under high heat and pressure to form the finished product.

2. The powder mixture is placed in a mold or container and heated to an elevated temperature so that it begins to melt and fuse.

3. Once the material reaches its melting point, it is held at this temperature for a period of time until it solidifies into one piece with no gaps or cracks between particles.

4. After solidification has occurred, the magnet can be machined into its desired shape and size using various cutting tools such as milling machines or lathes depending on the application specifications.

5. The edges of the magnet can then be polished smooth if desired before being coated with protective plating such as nickel or zinc for corrosion resistance purposes.

More details processing, please kindly see the bellow flow chart:

| No. | Process Flow | Production Step | Technological Operation |

|

1 |

Raw Material Inspection | 1.ICP-2.chemical Analysis-3.Analyser(C&S) | Rohs Detection Composition Test Purity Analysis |

|

2 |

Raw Material Pre-treatment | 4.Sawing- 5. Drying- 6.Impact Cleaning | Sawing Iron Hot Air Drying Impact Cleaning |

|

3 |

Ingredient Control | 7.Ingredient Control | Weigh Batching Mix Raw Material |

|

4 |

Strip Casting | 8.Vacuumizing-9.Melting-10.Casting | Vacuumizing Melting Smelting Casting |

|

5 |

Hydrogen Decrepitation | 11.Pre-treating-12.Vacuumizing-13.Add Hydrogen | Pre-treating Vacuumizing Demolish by Hydrogen |

|

6 |

Milling | 14.Shattering-15.Grinding-16.Jet Mill-17.Granularity Control | Shattering Grinding Jet Mill Rogular Measurement |

|

7 |

Pressing | 18. Powder weighting -19.Pre-pressing – 20.Pressing -21. Isostatic pressing | Powder weighting Pre-pressing Pressing Isostatic pressing |

|

8 |

Sintering | 22.Vacuumizing- 23.Sintering -24 Heat treatment | Vacuumizing Sintering Heat treatment |

|

9 |

Inspection | 25.B-H curve-26. PCT-27. Density test -28.Roughcast Inspection | Magnetic measurement Temperature coefficient test PCT Density Measurement Inspection |

|

10 |

Machining | 29.Grinding -30.Wire cutting-31.Inner blade cutting | Grinding Wire cutting Inner blade cutting |

|

11 |

QC sample test | 32.QC sample test | QC sample test |

|

12 |

Chamfering | 33.Chamfering | Chamfering |

|

13 |

Electroplating | 34.Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Chemical Ni | Electroplating Zn Electroplating NICUNI Phosphating or Chemical Ni |

|

14 |

Coating Inspection | 38.Thickness-39.Corrosion Resistance -40. Adhesiveness-41.-Tolerance Inspection | Thickness Corrosion Resistance Adhesiveness Tolerance Inspection |

|

15 |

Magnetization | 42.Complete Inspection- 43.Marking- 44.Arraying/Involution- 45.Magnetizing | Complete Inspection Marking Arraying/Involution Magnetizing Magnetic Fiux Test |

|

16 |

Packing | 46. Magnetic Flux- 47.Bagging- 48. Packing | Bagging Packing |

Post time: Feb-15-2023