Neodymium magnets have become a widely used material in modern industry, thanks to their high magnetic strength and resistance against demagnetization. They can be found in various applications, from speaker cones to MRI machines. One of the most important factors in determining the performance of neodymium magnets is their grade. In this article, we will discuss how to choose the grade of neodymium magnets to suit your needs.

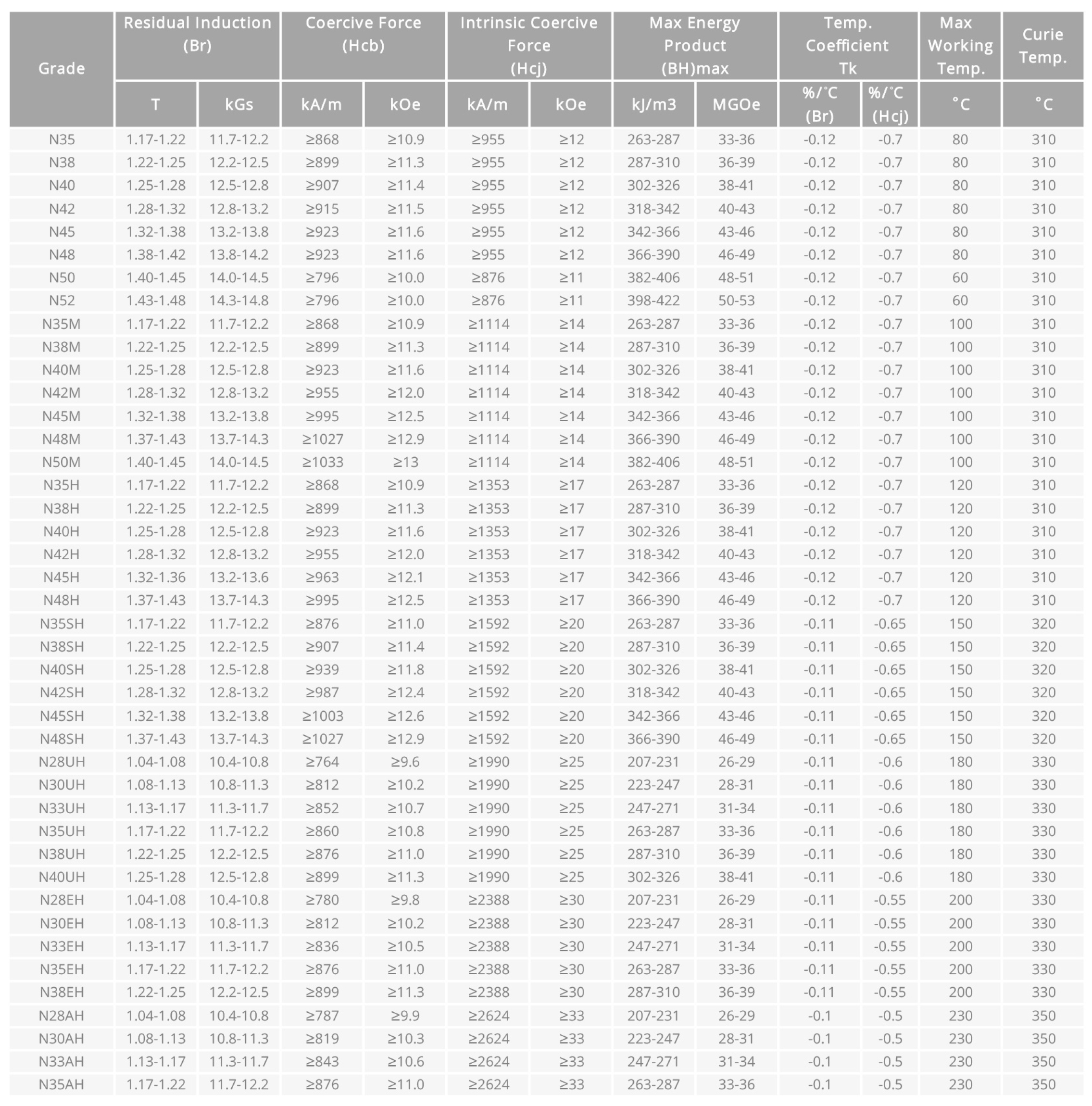

First, let’s talk about what a “grade” means in the context of neodymium magnets. Simply put, it refers to the strength of the magnetic field that the magnet can generate. Each grade is assigned a number, usually in the form of Nxx, where xx represents two digits that denote the maximum energy product of the magnet in mega gauss-oersteds (MGOe). The energy product is a measure of the magnetic field strength and density.

So, how do you determine which grade of neodymium magnet is best for your application? Here are a few factors to consider:

1. Application requirements: The first step is to identify the specific requirements of your application. What is the desired strength of the magnetic field? What temperature and environmental conditions will the magnet need to withstand? What size and shape of magnet do you need? Answering these questions will help you narrow down the range of grades that are suitable for your needs.

2. Cost: Neodymium magnets are relatively expensive compared to other magnet materials, such as ceramic magnets. Higher grade magnets usually have a higher price, so you’ll need to balance the performance requirements of your application against your budget.

3. Performance vs. size: The higher the grade of the magnet, the stronger the magnetic field it can generate. However, high-grade magnets can be brittle and difficult to machine or handle. If your application requires a smaller magnet, or if you need to fit the magnet into a tight space, a lower grade magnet may be more appropriate.

4. Temperature resistance: Neodymium magnets are sensitive to temperature changes, and the energy product of the magnet decreases as the temperature increases. Some grades of neodymium magnets are designed to withstand higher temperatures than others. If your application involves high-temperature environments, you’ll need to choose a grade that can maintain its magnetic strength under those conditions.

5. Coatings: Neodymium magnets are prone to corrosion and oxidation, so they are often coated with a protective layer of nickel or other metals. Some grades of neodymium magnets may require a different coating or surface treatment to suit your application.

In summary, choosing the right grade of neodymium magnets requires careful consideration of your application requirements, budget, and the magnet’s performance characteristics. Factors such as size, temperature resistance, and coatings can all play a role in determining which grade is best for your needs. Whether you are designing a new product or upgrading an existing one, selecting the right grade of neodymium magnet can make all the difference in achieving the performance you require.

Post time: Apr-11-2023