Ferromagnetic materials such as iron, cobalt, nickel or ferrite are different in that the internal electron spins can be arranged spontaneously in a small range to form a spontaneous magnetization region, which is called the domain. The magnetization of ferromagnetic materials, the internal magnetic domain neatly, the direction of the same line up, so that the magnetic strength, constitute a magnet.

All kinds of permanent magnetic materials, such as aluminum nickel and cobalt, samarium cobalt, ndfeb, these are also common, magnetic is very strong, these substances can be magnetization of the magnetic field of constant magnetic field, and after magnetization itself has a magnetic and don’t disappear. The composition of the artificial magnet depends on the magnetization performance of various metals and is determined according to the need. A magnet is close to (touching) a magnetic substance that is induced to an opposite pole near one end and to a pole of the same name at the other end.

A. Temporary (soft) magnet;

Significance: magnetism is transient and disappears when the magnet is removed. Example: nails, wrought iron.

B. Permanent (hard) magnet;

Significance: after magnetization, magnetism can be retained for a long time. Example: steel nail.

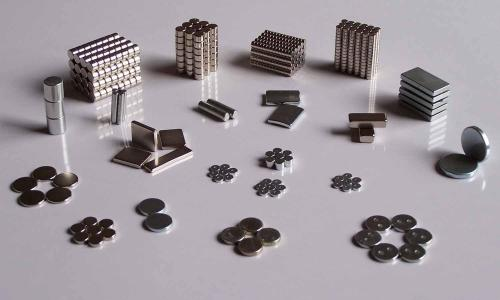

There are too many categories of magnets, I will simply say here:

There are two main categories of magnetic materials:

The first is permanent magnetic materials (also known as hard magnetic) : the material itself has the characteristics of magnetic preservation.

The second it is soft magnetism (also call electromagnet) : need outside electrify ability produces magnetic force, we are flat it is the magnet that says, it is to point to permanent magnet material commonly.

There are also two categories of permanent magnetic materials:

The first category is: alloy permanent magnetic materials including rare earth permanent magnetic materials (ndfeb Nd2Fe14B), SmCo (samarium cobalt), NdNiCO (neodymium nickel cobalt).

The second category is Ferrite permanent magnetic materials, which are divided into Sintered Ferrite, bonded Ferrite Magnet and injection Ferrite according to different production processes. These three processes are divided into isotropic and heterotropic magnets according to different orientation of magnetic crystals.

Post time: Feb-15-2023