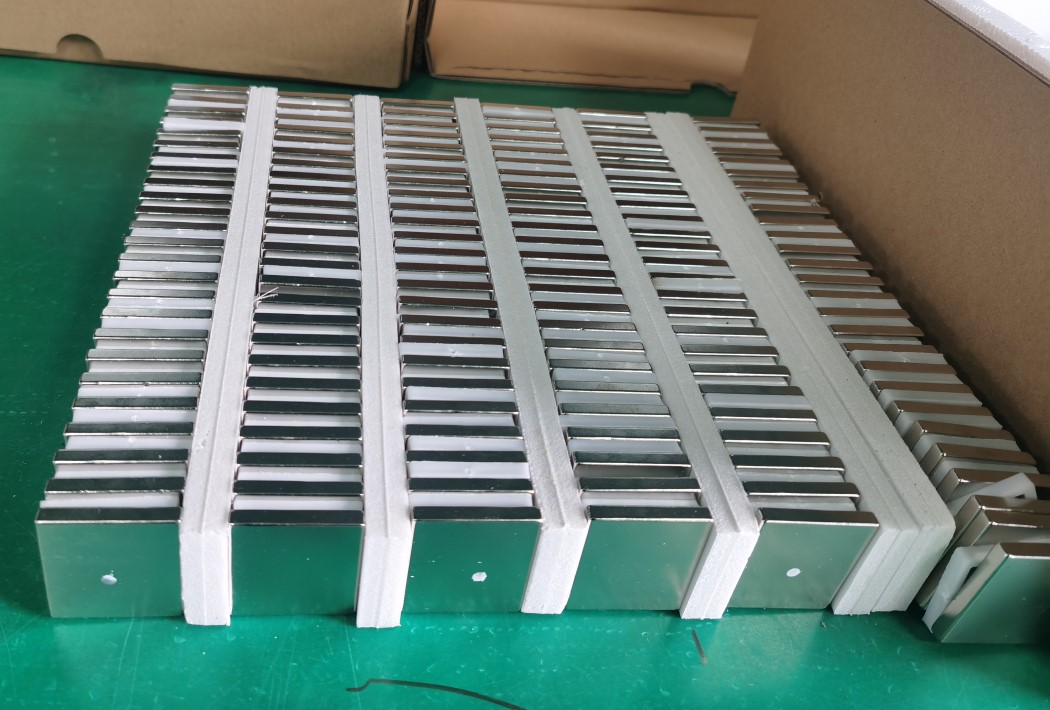

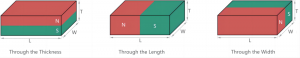

N38SH High Temperature Block Neodymium Magnet for motor

Product Description

Block neodymium magnets, also known as bar magnets, are among the most popular types of magnets for retail. They are extremely versatile in their use and achieve remarkable adhesive forces even at a small size. Responsible for that is the neodymium iron boron combination, which is currently the strongest available magnet material in the world.

|

Material |

Neodymium Magnet |

|

Size |

40mmx32.5mm x 5.4mm thick or as per customers' request |

|

Shape |

Block / Customized (Block, Cylinder, Bar, Ring, Countersunk, Segment, Trapezoid, Irregular shapes ,etc) |

|

Performance |

N38SH / Customized (N28-N52; 30M-52M;28H-50H;28SH-48SH;28UH-42UH;28EH-38EH;28AH-33AH) |

|

Coating |

NiCuNi, Nickel / Customized (Zn,Gold, Silver, Copper, Epoxy, Chrome, etc) |

|

Size Tolerance |

± 0.02mm - ± 0.05mm |

|

Magnetization Direction |

Through the thickness/width/length |

|

Max. Working |

150°C (320°F) |

|

Applications |

motors, sensors, microphones, wind turbines, wind generators, printer, switchboard,packing box , loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, ect. |

Disc Neodymium Magnet Advantages

1.Material

Neodymium magnets have outstanding magnetic properties (force and endurance) and are far better than Ferrite and AlNiCo magnets. The products’ cpk value of Br and Hcj is much higher than 1.67 with excellent consistency. The surface magnetism and magnetic flux consistency in the same batch of products can be controlled within +/-1%.

2.World's most precise tolerance

The tolerances of products can be controlled within ±0.05mm or even more.

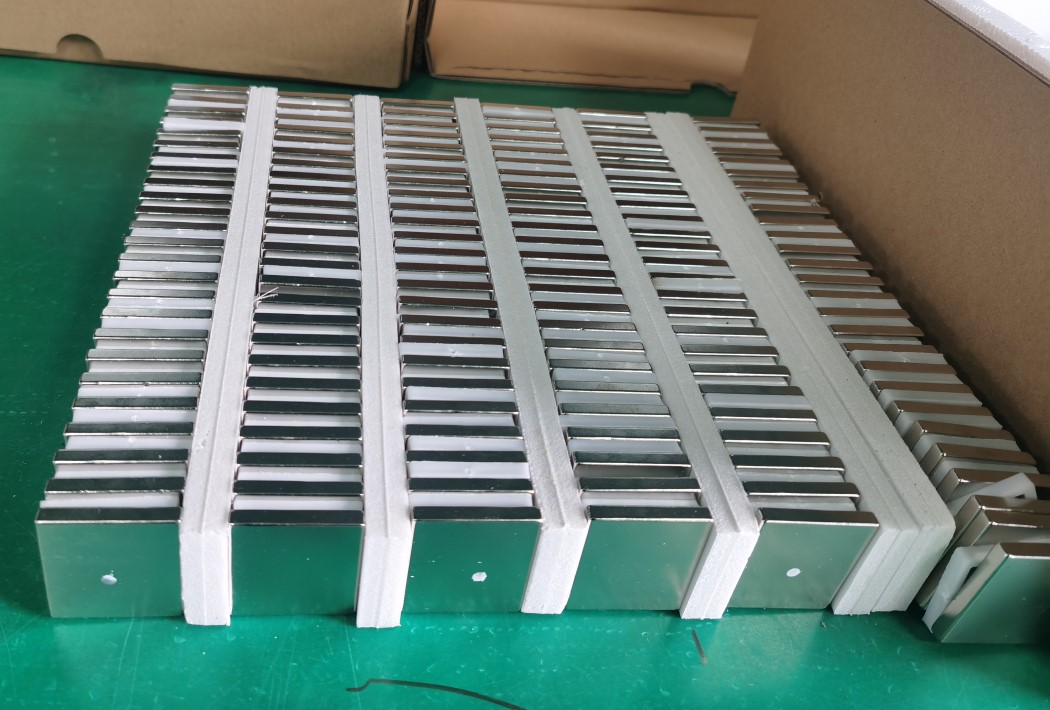

3.Coating / Plating

Neodymium magnets are a composition of mostly Nd, Fe, and B. If left exposed to the elements, the iron in the magnet will rust.

To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but Ni-Cu-Ni is the most common and usually preferred.

Other options of coating: Zinc, Black Epoxy, Rubber, Gold, Silver, PTFE etc.

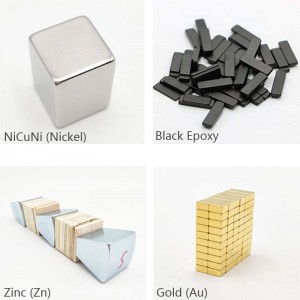

4.Magnetic Direction

The regular magnetic direction of the block magnet is through the thickness, through the length and through the width.

If the magnetization direction of the block magnet is thickness, the maximum pull force is on the top and bottom of the magnet.

If the magnetization direction of the block magnet is length, the maximum pull force is on the curved surface through the length of the magnet.

If the magnetization direction of the block magnet is width, the maximum pull force is on the curved surface through the width of the magnet.

Packing & Shipping

Our products can be shipped by air, express, rail, and sea. The tin box packaging is available for air freight, and standard export cartons and pallets are available for rail and sea transport.